All Hot Tapping Machines

LJ1-25 • T1-2 • T1M • T1- 4 • T1-8 • T1A • HP-104 • HP-106 • T-24E • T-30E • T-30H • T-30A • T-37H • T-37A • T46+ • T-60H • T-112LJ1-25-UP Hot Tapping Ultimate Package

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Designed light to maneuver, built smart to perform Don’t be Caught short! Full 11” of travel Competitors don’t have enough travel to satisfy Total Control of Travel for Safety Positive Retention of Coupons

Replacement and additional parts in stock Operating max. pressure:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

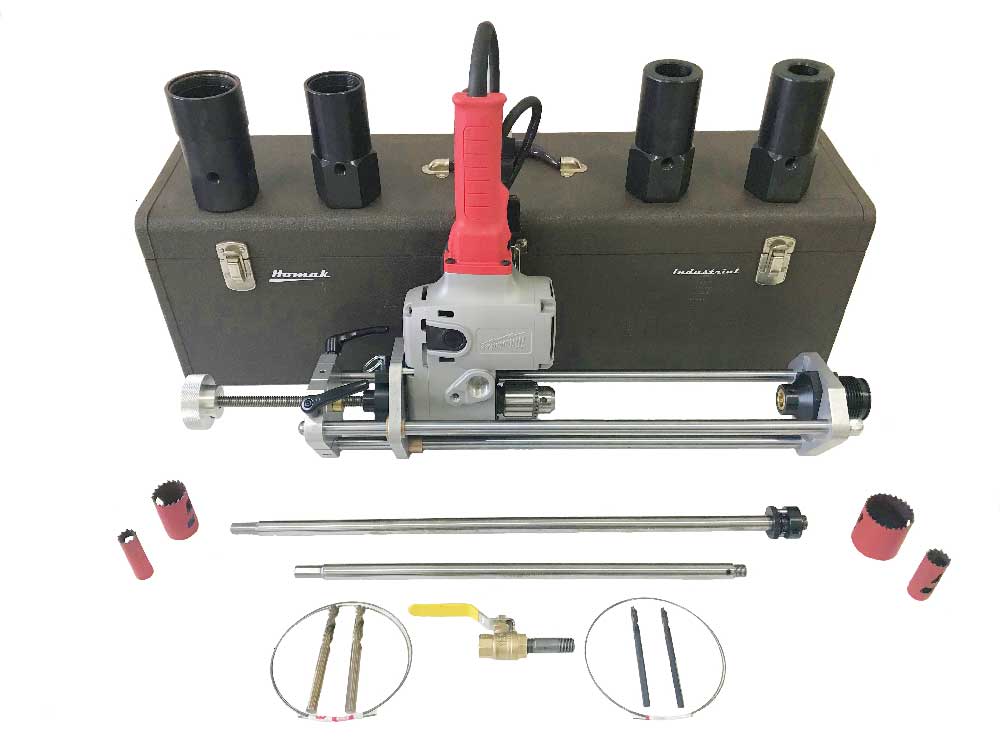

LJ1-25 Turn-Key 1"-2" Tap Package

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

LJ1-25-CP CTS Compression Tapping Package |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Designed light to maneuver, built smart to perform Don’t be Caught short! Full 11” of travel Competitors don’t have enough travel to satisfy Total Control of Travel for Safety Positive Retention of Coupons

Replacement and additional parts in stock Operating max. pressure:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

LJ1-25-CFP Copper Flare Hot Tap Package |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

T1-2-UP Hot Tapping Machine Ultimate Package |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Operating max pressure 300psi @ 100°F (std.packing) Don't be fooled by cheap imitations, we are the original manufacturer of the T1 series tapping machine!

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

T1-2 Turn-Key 3/4"-2" Package |

||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||

T1-4 Completing a 3" Hottap on 6.63" Steel Video:

Need a Technical Certification of Training?

Recently 2LBin.com sold the T1-2 hot tapping machine package to a company that also wanted to purchase our Technical Certification of Training via our Hot Tapping Specialists Training Program. The Hot tap was successful, coupon was retained and a completion certificate of training was issued. For more information about our hot tapping machines and services please call 1-800-279-5659.

T1-2-CP Hot Tapping Machine CTS Compression Package

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Operating max pressure 300psi @ 100°F (std.packing) Don't be fooled by cheap imitations, we are the original manufacturer of the T1 series tapping machine!

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

T1-2-CFP Copper Flare Turn-Key Package |

||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||

T1-4 Completing a 3" Hottap on 6.63" Steel Video:

Need a Technical Certification of Training?

Recently 2LBin.com sold the T1-2 hot tapping machine package to a company that also wanted to purchase our Technical Certification of Training via our Hot Tapping Specialists Training Program. The Hot tap was successful, coupon was retained and a completion certificate of training was issued. For more information about our hot tapping machines and services please call 1-800-279-5659.

T1-4-UP Hot Tapping Machine Ultimate Package

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Operating max pressure 300psi @ 100°F (std.packing) Don't be fooled by cheap imitations, we are the original manufacturer of the T1 series tapping machine!

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

T1-4 Turn-Key 3/4"-4" Package |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

T1-4 Completing a 3" Hottap on 6.63" Steel Video:

Need a Technical Certification of Training?

Recently 2LBin.com sold the T1-4 hot tapping machine package to a company that also wanted to purchase our Technical Certification of Training via our Hot Tapping Specialists Training Program. The Hot tap was successful, coupon was retained and a completion certificate of training was issued. For more information about our hot tapping machines and services please call 1-800-279-5659.

This Tapping Machine Taps:

|

High Pressure Line Contents

|

T1-M Adaptable Tapping Machine |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Converts T1-M to Electric power. Need to replace your old tapping machine but you don't want to replace all those adaptors? We have the Answer: Its the T1-M Operating max pressure 300psi@ 100°F (std.packing) “Adaptable to perform up to 4” Hot taps”

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

T1-M Turn-Key Package |

||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||

T1-4 Completing a 3" Hottap on 6.63" Steel Video:

Need a Technical Certification of Training?

Recently 2LBin.com sold the T1-2 hot tapping machine package to a company that also wanted to purchase our Technical Certification of Training via our Hot Tapping Specialists Training Program. The Hot tap was successful, coupon was retained and a completion certificate of training was issued. For more information about our hot tapping machines and services please call 1-800-279-5659.

T1-AirDrive Tapping Machine Only

|

||||||||||||||||||||||||||||||||||||||||||||||

The T1-A Tapping machine consists of a 3 rail frame in which the drive unit slides and operates off a 3/4 Horsepower Cleco Air Motor, requiring 90 – 100 PSI air pressure through a minimum 3/8” I.D. hose to create a spindle speed of 225 RPM. Behind the drive motor, the feed assembly slides and locks into place. The packing housing, consisting of 3 O-rings, at the opposite end of the feed assembly, seals around different length boring bars, depending on the travel needed to complete the tap. Different size adaptors screw on to the machine which are sealed by an existing O-ring for convenient size changes.

Operating max pressure 300psi@ 100°F (std.packing) Don't be fooled by cheap imitations, we are the original manufacturer of the T1 series tapping machine!

|

||||||||||||||||||||||||||||||||||||||||||||||

T1-AIRDrive Turn-Key 3/4"-4"Package

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

T1 Airdrive Hot Tapping Machine Video:

Need a Technical Certification of Training?

Recently 2LBin.com sold the T1-A hot tapping machine package to a company that also wanted to purchase our Technical Certification of Training via our Hot Tapping Specialists Training Program. The Hot tap was successful, coupon was retained and a completion certificate of training was issued. For more information about our hot tapping machines and services please call 1-800-279-5659.

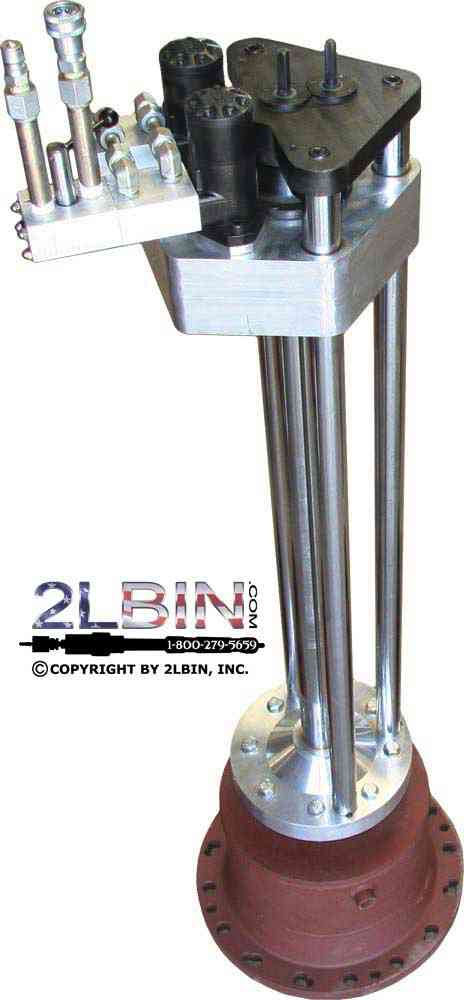

HP-104 Tapping Machine Only

|

||||||||||||||||||||||||||||||||||||||||||||

HP-104 High Pressure Hot Tap Machine CapabilitiesTap into any pipeline system, without a shut down, with our HP-106 hot tap drilling machine. This high pressure machine is operated manually, electrically, or pneumatically for making hot taps 1/2" - 6". Solid drills range from 1/2"-1 3/8" and hole-saw holders are used for 1 1/2” through 6”. The HP-106 is designed to perform hot taps with ease and safety. This model is compatible with IPSCO IP100 drilling machine parts and accessories. Video detailing replacement of the high pressure packing is here:) For more information please feel free to call us at 1-800-279-5659

Operating max. pressure:

|

||||||||||||||||||||||||||||||||||||||||||||

HP-104 Turn-Key 1/2"-4" Package |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High Pressure Hot Tapping Machine (HP-104 and HP-106) Completing a Demo Hottap:

HP-106 Tapping Machine Only |

||||||||||||||||||||||||||||||||||||||||||||

HP-106 High Pressure Hot Tap Machine CapabilitiesTap into any pipeline system, without a shut down, with our HP-106 hot tap drilling machine. This high pressure machine is operated manually, electrically, or pneumatically for making hot taps 1/2" - 6". Solid drills range from 1/2"-1 3/8" and hole-saw holders are used for 1 1/2” through 6”. The HP-106 is designed to perform hot taps with ease and safety. This model is compatible with IPSCO IP100 drilling machine parts and accessories. Video detailing replacement of the high pressure packing is here:) For more information please feel free to call us at 1-800-279-5659

Operating max. pressure:

|

||||||||||||||||||||||||||||||||||||||||||||

HP-106 Turn-Key 1/2"-6" Package |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High Pressure Hot Tapping Machine HP-104 and HP-106 Completing a Demo Hottap:

T1-8 Electric Hot Tapping Machine Only |

||||||||||||||||||||||||||||||||||||||

Operating max. pressure:

|

||||||||||||||||||||||||||||||||||||||

T1-8 Electric Complete Turn-key 4"-8" Package |

||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||

T1-8 Hot Tapping Machine Taps Wall

|

||||||||||||||||||||||||||||||||

T-24E Electric Hot Tapping Machine Only |

||||||||||||||||||||||||||||||||||||||

Operating max. pressure:

|

||||||||||||||||||||||||||||||||||||||

T-24E Electric Complete Turn-key 3"-8" Package

|

|||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||

T1-8 Hot Tapping Machine Taps Wall

|

|||||||||||||||||||||||||||||||||||||||

T-30E Tapping Machine Only

|

|||||||||||||||||||||||||||||||||||

Operating max. pressure:

|

|||||||||||||||||||||||||||||||||||

T-30E Complete Turn-key 3"-12" Package

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||

T-30 Hot Tapping Machine Taps Pipe for Insert Valve Installation |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

T-30H Tapping Machine Only

|

||||||||||||||||||||||||||||||||||||||

Operating max. pressure:

|

||||||||||||||||||||||||||||||||||||||

T-30H Complete Turn-key 3"-12" Package

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

T-30 Hot Tapping Machine Taps Pipe for Insert Valve Installation |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

T-30 Air Drive Hot Tapping Machine Only |

||||||||||||||||||||||||||||||||||||||

Operating max. pressure:

|

||||||||||||||||||||||||||||||||||||||

T-30 Air Drive Complete Turn-key 3"-12" Package |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

T-30 Hot Tapping Machine Taps Pipe for Insert Valve Installation. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

T-37H Tapping Machine Only

|

||||||||||||||||||||||||||||||||||||||

Operating max. pressure:

|

||||||||||||||||||||||||||||||||||||||

T-37H Complete Turn-key 3"-16" Package

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

T-30 or the T-37 Hot Tapping Machine Taps Pipe for Insert Valve Installation. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

T-37 Air Drive Hot Tapping Machine Only |

||||||||||||||||||||||||||||||||||||||

Operating max. pressure:

|

||||||||||||||||||||||||||||||||||||||

T-37 Air Drive Complete Turn-key 3"-16" Package |

||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||

T-30 Hot Tapping Machine Taps Pipe for Insert Valve Installation |

||||||||||||||||||||||||||||||||||||||||||||||||

T-46 Hydraulic Hot Tapping Machine Only |

||||||||||||||||||||||||||||||||||||||

Operating max. pressure:

|

||||||||||||||||||||||||||||||||||||||

T-46H Complete Turn-key 12"-24" Package |

||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||

T-46 Hot Tapping Machine Taps PipeThis video shows IFT performing a 24” hot tap, for the city of "Murrieta", on CMLC pipe. The T-46 “Big Louie” made a perfect tap; retaining the coupon within only a few hours. |

||||||||||||||||||||||||||||||||||||||

T-60 Hydraulic Hot Tapping Machine Only |

||||||||||||||||||||||||||||||||||||||

Operating max. pressure:

|

||||||||||||||||||||||||||||||||||||||

T-60H Complete Turn-key 12"-36" Package |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

T-46 Hot Tapping Machine Taps PipeThis video shows IFT performing a 24” hot tap, for the city of "Murrieta", on CMLC pipe. The T-46 “Big Louie” made a perfect tap; retaining the coupon within only a few hours. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

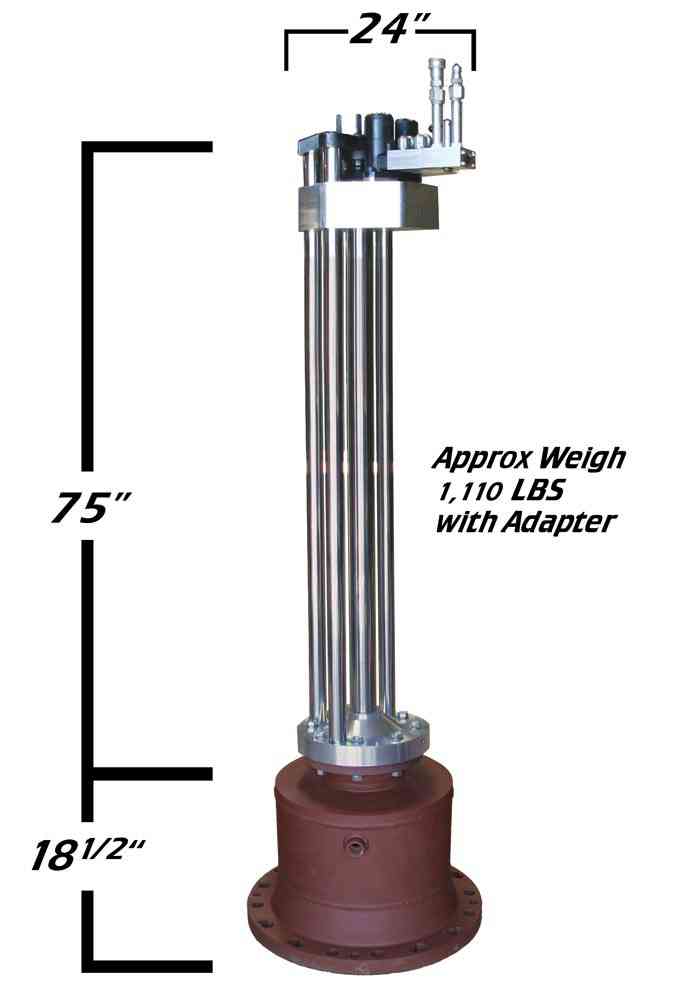

T-112 Hydraulic Hot Tapping Machine Only |

||||||||||||||||||||||||||||||||||||

Operating max. pressure: Owners Manual coming soon

|

||||||||||||||||||||||||||||||||||||

T-112H Turn-key Package |

||||||||||||||||||||||||

|

||||||||||||||||||||||||

T-112 Hot Tapping Machine PackageThis video shows the T-112 packaged up and ready to ship to its happy owner in Mexico. |

||||||||||||||||||||||||

Leave us a Facebook Comment